From the Darlington & Stockton Times of March 16, 1872

“ECONOMY in building”, said the D&S Times’ headline in the edition of 150 year ago this week, and it told how an entrepreneur called Joseph Woodward, of Darlington, was creating a product which would become one of the defining features of our area.

“On Wednesday, some experiments in the matter of the construction of the new bricks – which are made out of slag – were carried out at the works of one of the most eminent firms in Cleveland,” said the report.

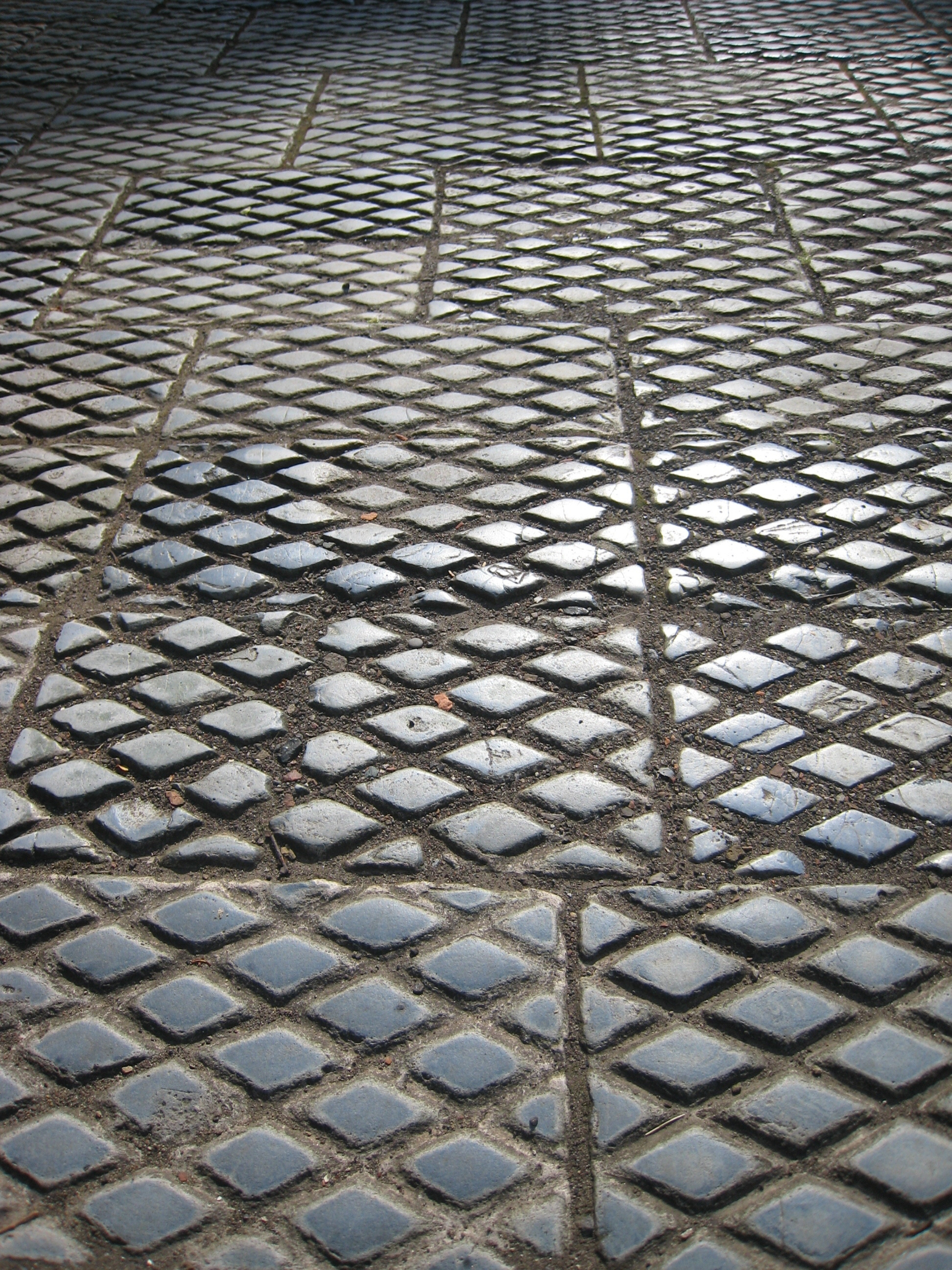

This is the shiny, blue-grey scoria brick. The slag brick.

A scoria brick with the name of Joseph Woodward's company, the Tees Scoria Brick Company, pressed into it

The blast furnaces of Middlesbrough produced huge quantities of slag which was just tipped onto the boggy saltplains until Mr Woodward had the bright idea of pouring the molten slag into moulds, reheating it and then tipping it out as bricks.

“Knowing what we know, we need scarcely say that the experiments were highly successful,” said the D&S. “Some who might have entertained doubts as to the practicability of Mr Woodward’s patent were fairly converted by what they saw on Wednesday. The fact is significant enough.”

Scoria bricks in a gutter with the name of Joseph Woodward's company, the Tees Scoria Brick Company, pressed into them

They saw that slag bricks are almost unbreakable and they are waterproof.

They were used to line the earthen floors of the disease-ridden yards so that piles of effluent could be rinsed out, and they lined gutters so water would run away.

Much of south Durham and the Tees Valley was lined with them – their durability meant that they could withstand the iron-rimmed wheels of horsedrawn carriages.

Having lined the Tees Valley, he exported. In 1912, 62,881 tons of scoria bricks were shipped from Teesmouth, with 37 per cent going to Canada and 36 per cent to the West Indies. Rotterdam is to this day lined with Tees Valley slag.

As Mr Woodward refined his operation so his designs became more sophisticated. Today, his interlocking hexagonal slag bricks make an attractive driveway leading to the poshest of homes.

A lane in the Eastbourne area of Darlington, lined a fancy pattern of scoria bricks

The durable bricks were ideal for withstanding the impact of metal-rimmed wheels of horsedrawn carriages, but when motor cars came along, drivers wanted a smoother ride and so all major roads were tarmacked, relegating the scoria bricks to the back alleys. Mr Woodward’s company eventually went bankrupt in 1966 and was wound up in 1972.

However, as his manufacturing processes had become more sophisticated, some of his scoria designs had become more decorative – his double hexagonal interlocking bricks are a joy to behold. They have become sought after as design features in driveways leading to the poshest houses in the area, proving the really is mortar bricks than meets the eye.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here